1. Definition and chemical structure

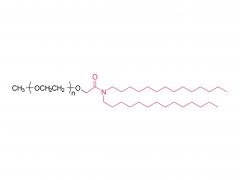

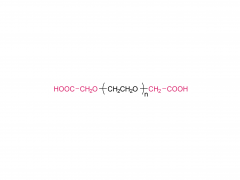

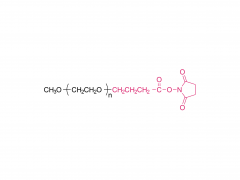

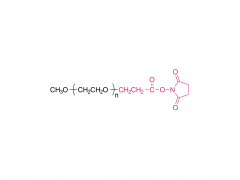

mPEG-MA, full name Methoxy Polyethylene Glycol Methacrylate, is a bifocal compound consisting of the following two parts:

Methoxy-polyethylene glycol (mPEG) chain: as the main chain of hydrophilic polymerization, giving the molecule good water solubility.

Methacrylate (MA) end group: provides an active site for polymerization or modification with a variety of functional groups (such as hydroxyl, amino).

Molecular weight: can be customized according to requirements, common specifications include 1k, 2k, 3.4k, 5k, 10k, 20k, etc.

2. Physical and chemical properties

Solubility: Dissolved in DMSO, DMF, dichloromethane (DCM), chloroform and other organic solvents.

Biocompatibility: mPEG segments have good biocompatibility and low immunogenicity, making them suitable for in vivo applications.

Reactivity: methacrylate groups can be combined with other monomers through free radical polymerization, esterification reaction, etc., to form functional materials.

3. Main application areas

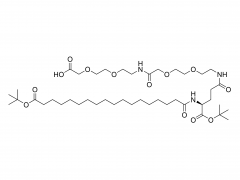

(1) Drug delivery system

Function: As a drug carrier, nanoparticles or micelles can be formed through copolymerization to improve the stability and targeting of drugs.

Advantages: Hydrophilic mPEG chain reduces protein adsorption and prolonging drug cycle time; Methacrylate groups can be introduced into targeting ligands (such as antibodies).

(2) Biomedical materials

Medical dressings: Use their biocompatibility and degradability for wound repair and skin regeneration.

Tissue engineering scaffolds: Porous scaffolds are prepared by copolymerization to support cell adhesion and growth.

(3) Industrial applications

Concrete admixture: as an intermediate of polycarboxylic acid superplasticizer, it can improve the fluidity and strength of concrete.

Coatings and adhesives: Used as solubilizers or crosslinkers to improve adhesion and weather resistance of coatings.

Emulsifier: Used as a natural non-toxic emulsifier in foods (such as dairy products) and cosmetics.