In modern materials science and biological applications, a class of highly flexible functional substances is increasingly becoming a key force driving technological breakthroughs—these are customizable PEGylated lipids. They are not traditional single products, but rather "personalized solutions" that can be adapted to the needs of different scenarios through precise adjustment of structure and properties. From healthcare to industrial production, their unique customizable attributes are bringing new possibilities to multiple industries.

I. What are Customizable PEGylated Lipids?

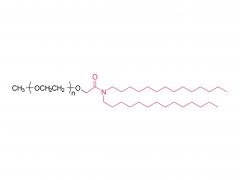

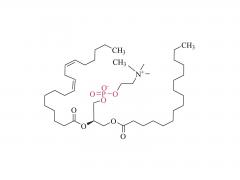

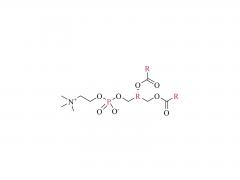

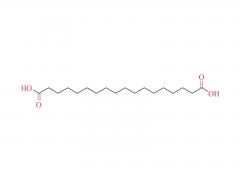

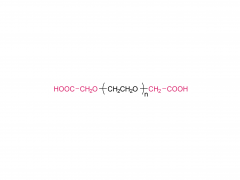

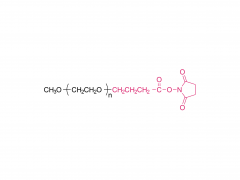

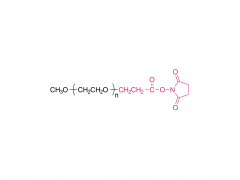

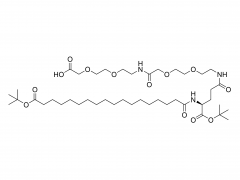

Simply put, PEGylated lipids are composite substances formed by combining a "lipid backbone" with "PEG segments" (polyethylene glycol chains), and "customizability" is their core advantage. Unlike standardized products with fixed specifications, their key molecular components can be adjusted according to the requirements of specific applications: for example, modifying the length and density of PEG chains, optimizing the hydrophilicity/hydrophobicity of the lipid backbone, or even introducing special functional groups. This customization capability allows them to retain core properties such as stability and biocompatibility while precisely matching the personalized material requirements of different fields, much like a functional carrier "tailor-made" for specific tasks.

II. Core Customization Dimensions of Customizable PEGylated Lipids

Customizability is not an abstract concept but is realized through specific structural adjustments, primarily focused on three core dimensions. The combination of these dimensions can create a myriad of product forms:

-

PEG Segment Customization: Adapting to Different "Spatial Requirements"

The PEG segment is the key part determining the "interfacial properties" of the substance. By adjusting the molecular weight of the PEG chain (ranging from a few hundred to tens of thousands), its dispersion ability in liquids, repulsion force with other substances, and the thickness of the protective layer formed at interfaces can be altered. For instance, in scenarios requiring long-term retention, longer PEG chains can be chosen to enhance stability in the target environment, while in scenarios needing rapid release, shorter PEG chains can reduce hindrance and improve reaction efficiency. Simultaneously, the density of PEG chains can also be customized; high-density chains form a tighter protective barrier, while low-density chains reserve more space for other functional molecules to bind. -

Lipid Backbone Customization: Matching Different "Environmental Adaptability"

The lipid backbone determines the substance's "solubility" and "bioaffinity." Depending on the application, different types of lipid structures can be chosen. For aqueous environments, a lipid backbone with high water solubility can be customized to ensure uniform dispersion. For in vivo biological applications, a lipid backbone similar to cell membrane components can be customized to reduce rejection by the body and enhance biosafety. Additionally, the stability and lifespan of the substance can be optimized by modifying the branched structure of the lipid backbone. -

Functional Group Customization: Enabling "Specialized Functions"

To meet functional needs in specific scenarios, dedicated functional groups can be introduced into the molecular structure of the PEGylated lipid. For example:-

In targeted delivery, targeting groups that bind to specific cell surface receptors can be introduced, enabling precise "recognition" and action on specific sites.

-

In responsive release systems, groups sensitive to temperature, pH, or specific molecules can be introduced, allowing the substance to release its functional payload only under specific conditions.

-

In sensing and detection, chromogenic or luminescent groups that undergo specific reactions with target substances can be introduced, enabling rapid detection and signal feedback.

-

III. Diverse Application Value of Customizable PEGylated Lipids

Leveraging their flexible customization capability, customizable PEGylated lipids have demonstrated irreplaceable value in multiple fields, serving as crucial support for technological advancement and product innovation:

-

Healthcare: Enhancing Treatment Precision and Safety

-

Drug Delivery: By customizing PEGylated lipids with targeting functions, drugs can be encapsulated into nano-carriers for precise delivery to diseased areas like tumors or inflammation sites, reducing damage to healthy tissues and improving therapeutic efficacy. For cancer treatment, customized targeted PEGylated lipid carriers can concentrate chemotherapy drugs on cancer cells, lowering side effects.

-

Vaccine Development: PEGylated lipids with adjuvant functions can be customized to enhance vaccine immunogenicity while improving stability and shelf-life.

-

Biodiagnostics: Customized PEGylated lipids can serve as carriers for detection reagents, improving assay sensitivity and specificity, aiding in early disease detection and diagnosis.

-

-

Daily Chemicals & Cosmetics: Optimizing Product Experience and Efficacy

-

Skincare: As carriers for active ingredients (like Vitamin C, hyaluronic acid), their structure can be adjusted to enhance skin barrier penetration and absorption efficiency. Customized PEGylated lipids with moisturizing functions can form breathable hydrating films on the skin.

-

Cosmetics: PEGylated lipids with good dispersibility and stability can improve application smoothness and wear-time of makeup while reducing skin irritation and allergy risk.

-

Oral Care: PEGylated lipids that bind to tooth surfaces can be customized to fix antibacterial agents there, prolonging antibacterial action and preventing caries/periodontal disease.

-

-

Industrial & Environmental Fields: Promoting Green Production and Efficient Management

-

Industrial Catalysis: As catalyst carriers, their structure can be optimized to improve catalyst dispersion and active sites, enhancing reaction efficiency while reducing catalyst loss and production costs.

-

Coatings: PEGylated lipids with high adhesion and corrosion resistance can serve as film-forming or modifying agents, improving coating durability and environmental friendliness, and reducing VOC emissions.

-

Environmental Remediation: PEGylated lipids that bind to specific pollutants (heavy metals, organic contaminants) can be used for adsorption/removal in water treatment. Biodegradable PEGylated lipids can be designed to degrade naturally after use, avoiding secondary pollution.

-

-

Food & Agriculture: Ensuring Food Safety and Improving Crop Yield

-

Food Industry: As food additives, they can improve texture and stability. In dairy products, emulsifying PEGylated lipids prevent fat separation. In functional foods, they act as carriers for nutrients (probiotics, vitamins), promoting survival and absorption.

-

Agriculture: As pesticide synergists, they can enhance adhesion and penetration on crops, reducing pesticide usage and environmental impact. PEGylated lipids with water-retention functions can be used for soil improvement in arid areas.

-

IV. Customization Process and Quality Assurance for PEGylated Lipids

Achieving high-quality customizable PEGylated lipids requires a rigorous process and robust quality assurance system to ensure the final product precisely matches requirements:

-

Requirement Communication: Clarifying Core Needs

The first step involves in-depth discussions to fully understand the application scenario, functional requirements, performance indicators (stability, solubility, biocompatibility, etc.), and environmental constraints (temperature, pH, biological contact, etc.). A detailed requirement list provides clear direction for subsequent design. -

Structural Design: Scientifically Matching Requirements

Based on the requirements, a professional R&D team designs the molecular structure. Using computer simulation and experimental data, key parameters (PEG chain length/density, lipid backbone type, functional group type/position) are determined to ensure the design meets functional needs while being feasible and stable. -

Pilot Testing & Optimization: Verification and Adjustment

Small batches are produced based on the design and tested (performance, stability, biocompatibility, etc.). If deviations exist, structural parameters are adjusted and optimized iteratively until the sample meets specifications. -

Scale-up Production & Quality Control: Ensuring Consistency and Reliability

After successful pilot testing, batch production begins. Standardized processes and strict quality control ensure consistent performance and stable quality for each batch. Comprehensive testing (purity, structural characterization, functional validation) is conducted, and detailed quality reports are provided.

Future Outlook

As technology advances, customizable PEGylated lipids will develop towards smarter and greener directions.

-

Smart Customization: Integration with AI, using big data and machine learning for rapid requirement-structure matching, shortening development cycles. Development of multi-responsive functional groups will enable autonomous functional adjustment in complex environments.

-

Green Development: Increased use of renewable raw materials for lipid backbones and PEG segments, reducing reliance on fossil resources. Research into fully biodegradable PEGylated lipids will minimize environmental persistence, promoting sustainable development.