Polyethylene Glycol (PEG) Derivatives: The "Invisibility Cloak" and Potentiator Master in Modern Medicine

September 4,2025.

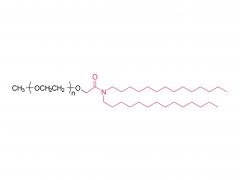

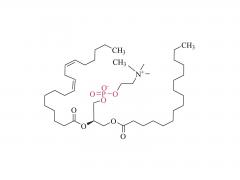

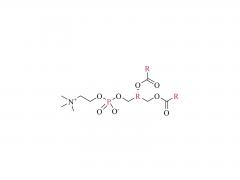

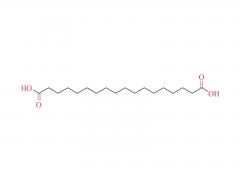

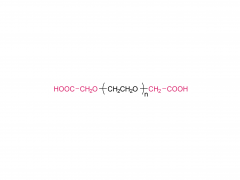

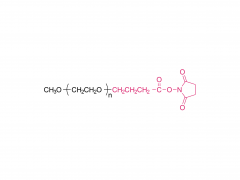

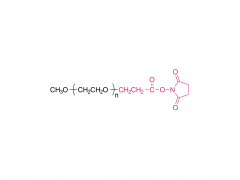

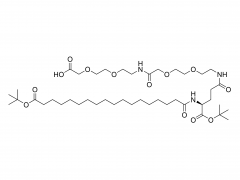

At the forefront of modern drug development, polyethylene glycol (PEG) derivatives play a crucial role. They act like an "invisibility cloak" for drug molecules, significantly enhancing therapeutic efficacy and safety, representing a revolutionary technology in the field of pharmaceutical chemistry. 1. What are Polyethylene Glycol (PEG) Derivatives? Polyethylene Glycol (PEG) is a linear, water-soluble, highly biocompatible polymer synthesized from the polymerization of ethylene oxide. It is non-toxic, non-immunogenic, and has been approved by the U.S. FDA as a safe chemical substance for oral, injectable, and topical use. PEG derivatives specifically refer to those PEG molecules that have been chemically modified to carry specific reactive functional groups (e.g., amino, carboxyl, maleimide, N-hydroxysuccinimide ester) at one or both ends of their molecular chains. These functional groups act like "grappling hands," enabling covalent binding to specific groups (e.g., amino, thiol groups) on proteins, peptides, antibodies, small molecule drugs, and even nanoparticles (like liposomes). This process is known as "PEGylation". Through PEGylation, one or more PEG chains are attached to the drug molecule, fundamentally altering its physicochemical properties and in vivo behavior. 2. Applications in Modern Medicine As a mature drug delivery and improvement strategy, PEGylation technology is extremely widespread in modern medicine, primarily serving the following purposes: Increase Drug Solubility: Many hydrophobic drugs have poor solubility in water, making them difficult to formulate into injectable solutions. Attaching hydrophilic PEG chains can significantly enhance a drug's aqueous solubility. Prolong Half-life, Reduce Dosing Frequency: ①Increase Molecular Size: The addition of PEG chains significantly increases the drug's molecular weight, making it less likely to be filtered through the glomeruli, thereby slowing renal clearance. ②Reduce Immune Recognition: The PEG chain acts like a protective shield, enveloping the drug surface, masking its antigenic epitopes, and reducing the chance of recognition and clearance by the immune system. ③Hinder Enzymatic Degradation: This same shielding effect also reduces the rate at which the drug is degraded by hydrolytic enzymes like proteases. Reduce Immunogenicity and Toxicity:For protein-based drugs (e.g., enzymes, cytokines), PEGylation can mask their heterologous nature, reducing the likelihood of the body producing antibodies, thus minimizing allergic reactions. It can also modify toxic functional groups of certain drugs, improving their safety profile (therapeutic window). Enhance Targeting (Passive Targeting): By prolonging the drug's circulation time in the bloodstream via PEGylation, the drug is more likely to accumulate in tissues with leaky vasculature, such as tumors or inflamed sites, through the Enhanced P...

View More